Radiation Tidbits - Safety Inspection of Radiation Laboratory

Written by: Yeung Siu-wai

The Observatory's Radiation Laboratory received ISO 9001:2008 accreditation of the International Organization for Standardization for its radiation measurement services this year. This is a recognition that the quality management implemented in the Radiation Laboratory had met the international standard. One of the most important management tasks is the inspection of radiation safety in the laboratory. This article introduces the equipment currently used in the laboratory for monitoring the radiation level of the worker and the indoor environment.

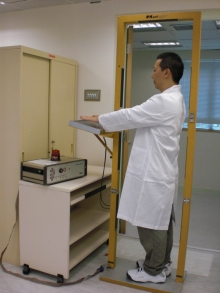

- Portal monitor

As the laboratory is used for measuring the radiation level of radionuclides in environmental samples, of which the radiation levels are in general very low, the background radiation of the laboratory must be maintained at a very low and stable level to ensure the accuracy of measurement. Laboratory worker, if contaminated, may bring the radioactive substances into the laboratory. In order to check quickly whether a worker is contaminated by radioactive substances, a portal monitor is installed at the entrance of the laboratory. A number of scintillation detectors fixed on the frame of the portal monitor detect the radiation level of different parts of the worker's body, including the head, shoulders, hands and feet. A worker entering or leaving the laboratory is required to stay within the frame of the monitor for 10 seconds or so. The monitor automatically measures the gamma rays released from different parts of the worker's body. Once the detected radiation level exceeds a preset warning limit, it will trigger a red light and an audible alarm from the monitor, and at the same time, a display on screen will show the parts of body that have exceeded the radiation level. In such a case, the worker should not enter the laboratory to avoid contaminating the area. He/she should decontaminate the body as soon as possible. If the monitor alarm sounds when the worker leaves the laboratory, the worker may have been contaminated by radioactive substances during his/her work inside the laboratory. Both the laboratory and the worker have to be decontaminated immediately.

The portal monitor measuring gamma radiation released from different parts of the body

The portal monitor is easy to operate. The public could readily operate the portal monitor exhibited

during the Observatory's Open Day. - Work area monitor

In addition to monitoring the radiation level of the laboratory workers, the inspection of the ambient environment inside the laboratory is also important. A work area monitor is used to detect radiation in this case. When radiation passes through the Geiger tube in the monitor, it ionizes the gas inside and produces electric current pulses. The pulse frequency is counted by electronic equipment and the radiation intensity can then be calculated and shown on the monitor. When the detected radiation level of the laboratory exceeds a preset warning limit, the monitor will give an audible alarm. Depending on the nature of work in the laboratory, different models of Geiger tube are used with the work area monitor to detect different types of radiation such as alpha, beta or gamma radiation.

The work area monitor uses a Geiger tube (the metallic tube in the diagram) to detect radiation - Portable contamination survey meter

Whenever a radioactive substance is handled in the laboratory, such as the use of radioactive calibration source to calibrate instrument, or the measurement of samples of high radioactivity, there is a possibility that the working bench, tools or floor of the laboratory and the worker's body are contaminated by the radioactive substance. The contaminant, like dust, may deposit on the surface of objects. It may also attach to objects through chemical or physical reaction. Therefore, on completion of a work involving radioactive substance, the laboratory worker and the facilities should be checked for surface contamination. If contamination is confirmed, decontamination must be done as soon as possible to avoid any detrimental effect to the worker's health and introducing errors to the measurement.

The Observatory uses a portable survey meter to check the surface contamination of laboratory worker and facilities such as table, floor and telephone. Inside the survey meter, there is a proportional counter tube for radiation detection. It works on a similar principle as the Geiger tube, but with different gases and a lower operating voltage. The gas inside the tube will be ionized by radiation and produce current pulses. In addition to the calculation of radiation level based on the number of pulses, the proportional counter tube can also distinguish between the types of radiation according to the properties of the gas inside. The Observatory currently uses the alpha and beta particle counting tube, which contains butane gas, to detect surface contamination.

The portable contamination survey meter checking for surface contamination

Back to Top

Back to Top